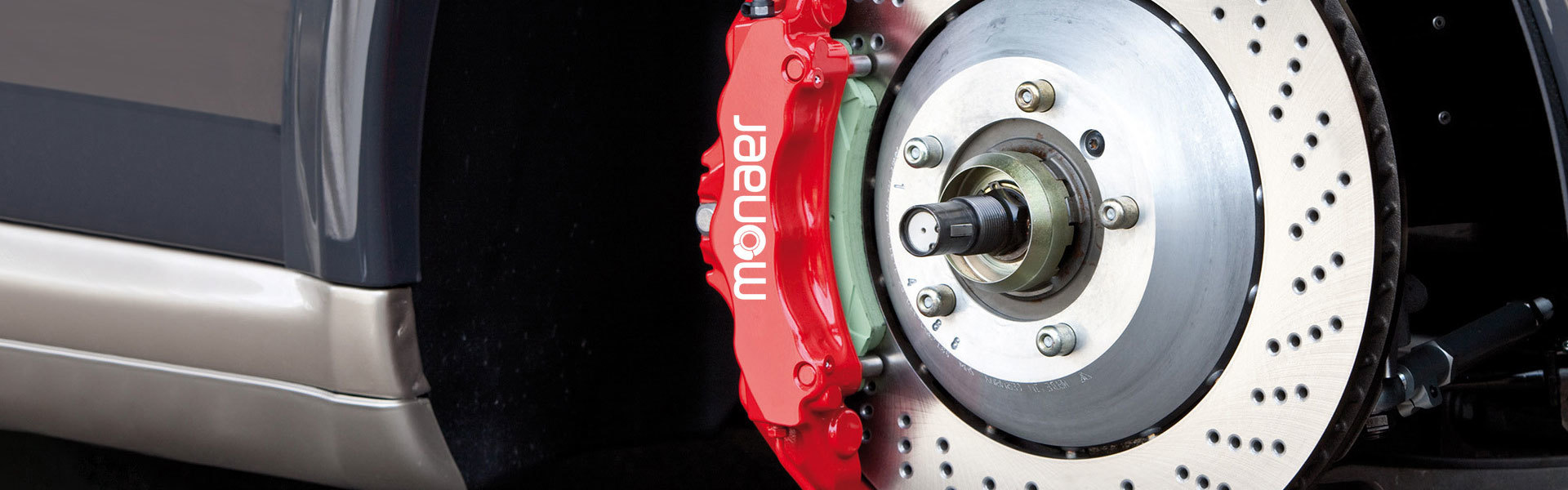

Performance

The raw materials used in friction materials each serve distinct purposes—such as influencing effectiveness, solidification, and wear resistance. By drawing on years of experience and accumulated data, XIANGLONG refines the braking feel for sports pads from among a diverse range of raw material combinations.

Chamfer Design

★ Adopting special chamfering design;

★ Effectively reducing noise and improving product heat dissipation performance;

Design of Titanium Carbon Alloy Coating

★ Adopting a unique titanium carbon alloy coating design;

★ Improve the initial running in performance of brake pads and brake discs;

★ Accelerated running in;

Unique Raw Materials

★ Adopting unique EG friction enhancing composite material and nylon 6 high-strength resin;

★ Effectively improving product comprehensive performance;

0.366-0.55 High Friction Coefficient

★ Adopting ABS exclusive high sensitivity formula and 100% imported raw materials;

★ Providing excellent comfort while providing high friction coefficient to ensure safety;

Unique Silencer

★ Adopting high-end imported composite materials and a four layer damping structure;

★ Beautiful while providing excellent noise reduction and silencing functions for brake pads;

High-precision Stamping Back Plate

★ Standard thickness: 5.5-6mm;

★ Cutting surface integrity ≥98%;

Production Capacity

Production System

The company has intemational advanced production lines, annual output capacity of 300 milion brake sets, more than 1,600 species, products used for most vehicles in worldwide. We have our own mould development centre, we can develop new products according to customer requirements.

Quality Control

By executing all production processes internally, XIANGLONG ensures stringent quality control and meticulous quality checks throughout each stage. This comprehensive in-house production system guarantees a consistent supply of high-quality products. Especially in the thermoforming process, which involves compressing friction materials under heat and pressure, requires precise control of temperature, pressure, and gas venting timing. These variables, which differ based on material, significantly influence the performance of the product.

PRODUCT SEARCH

Search And Quickly Find The Products You Need

The company's products can meet the personalized needs of different customers, and we sincerely provide customers with high-quality products and customized services. Our products are exported to Europe, America, the Middle East, Southeast Asia, Africa and other countries, and are sold well in various markets.

Continue Search OR Contact Us